ROLLS DIVISION

SG IRON PEARLITIC ROLLS

Microstructure of SG

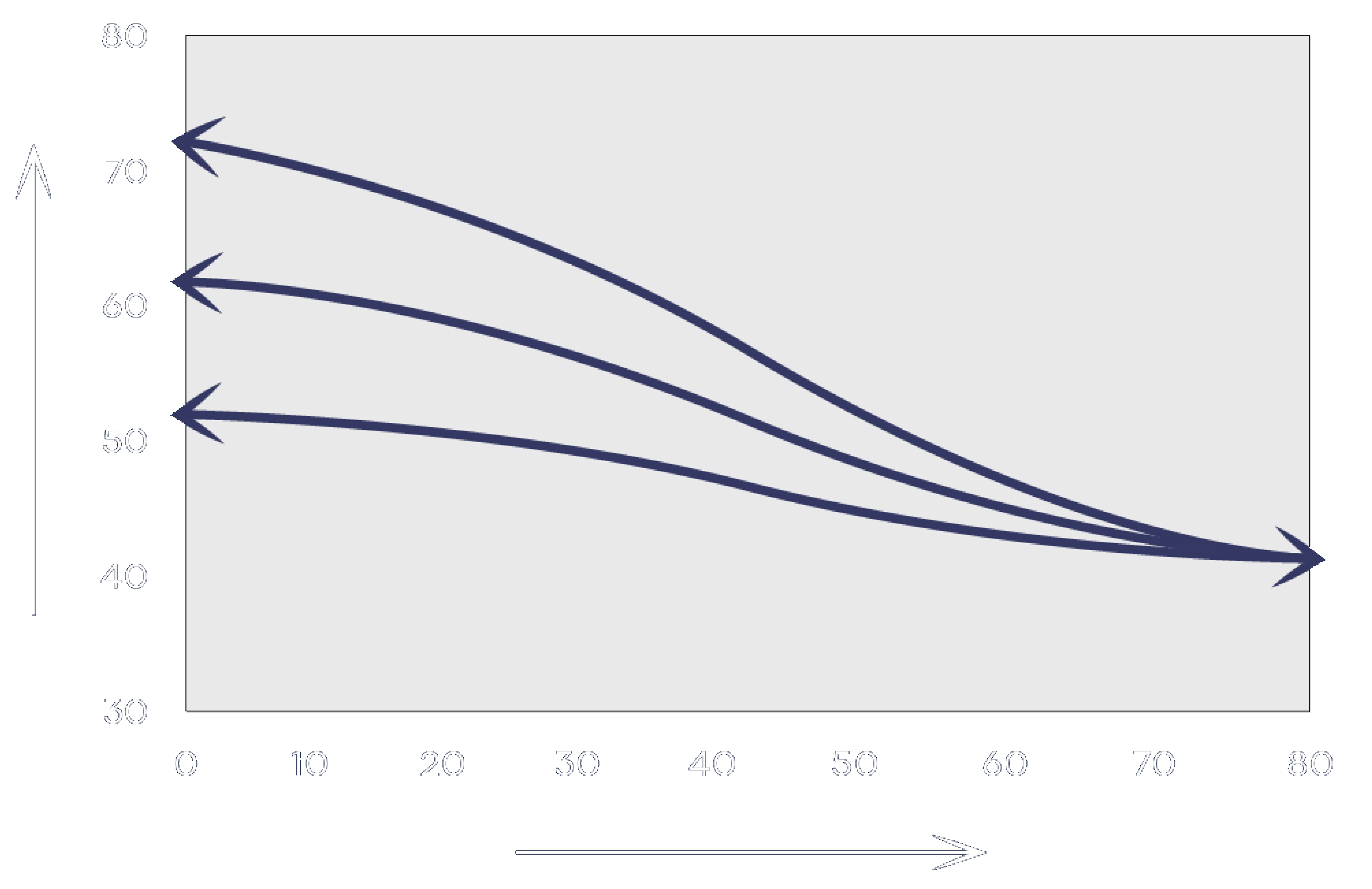

accicular rolls

Distance from surface - mm

Hardness - ShC

CHARACTERISTICS

S.G.L. Accicular Rolls are stronger and more wear-resistant than S.G.I. Pearlitic Rolls and are capable of achieving much higher hardness. They are alloyed with a higher percentage of Nickel and Molybdenum compared to S.G.I. Pearlitic, resulting in Accicular rolls with a bainitic matrix and increased carbide. The name of this material is based on its constituents of nodular graphite and carbides in an accicular (needle-like) bainitic matrix, also known as Lower Bainitic. These rolls are highly suitable for a wide range of applications due to their hardness penetration, good wear and heat resistance. Intensive water cooling of rolls is necessary to ensure the best performance.

SUPPLY CONDITIONS

- CO2 PROCESS

- PROOF MACHINED

- FINAL SIZE MACHINED/ BEARING SIZE

- HEAT TREATMENT

- GRADE CONFIRMATION THROUGH SPECTROMETER AND UTM MACHINE

CHEMICAL COMPOSITION

| SYMBOL | HARDNESS (SH-D) |

C% | MN% | SI% | S% | P% | CR% | NI% | MO% | UTS KGL/MM.SQ |

| SGP-40 | 40-50 | 3.00 3.30 |

0.30 0.50 |

1.80 2.30 |

0.015 MAX |

0.080 MAX |

0.20 MAX |

2.00 3.00 |

0.60 0.90 |

60-70 |

| SGP-50 | 50-60 | 3.00 3.30 |

0.30 0.50 |

1.80 2.30 |

0.015 MAX |

0.080 MAX |

0.50 MAX |

2.00 3.00 |

0.70 1.00 |

55-70 |

| SGP-60 | 60-70 | 3.10 3.50 |

0.50 0.80 |

1.30 2.00 |

0.015 MAX |

0.080 MAX |

0.30 0.80 |

2.00 3.50 |

0.80 1.20 |

50-70 |

| SGP-70 | 70-75 | 3.10 3.50 |

0.50 0.80 |

1.30 2.00 |

0.015 MAX |

0.080 MAX |

0.30 0.80 |

2.50 4.50 |

0.80 1.20 |

50-70 |

APPLICATIONS

These rolls are suitable for Intermediate and Finishing Mill stands for TMT Bar Mills, Rail and Structural mills. Rolls for Finishing Stands of Wire rod and Strip Mills.